Top 6 Applications of HDPE Butt Fusion Machines in Infrastructure Projects

- Share

- Issue Time

- Aug 5,2025

Summary

HDPE butt fusion machines play a critical role across diverse infrastructure sectors—from clean water and gas to mining and agriculture. Understanding where and how to deploy the right equipment can help your project meet performance, safety, and budgetary requirements.

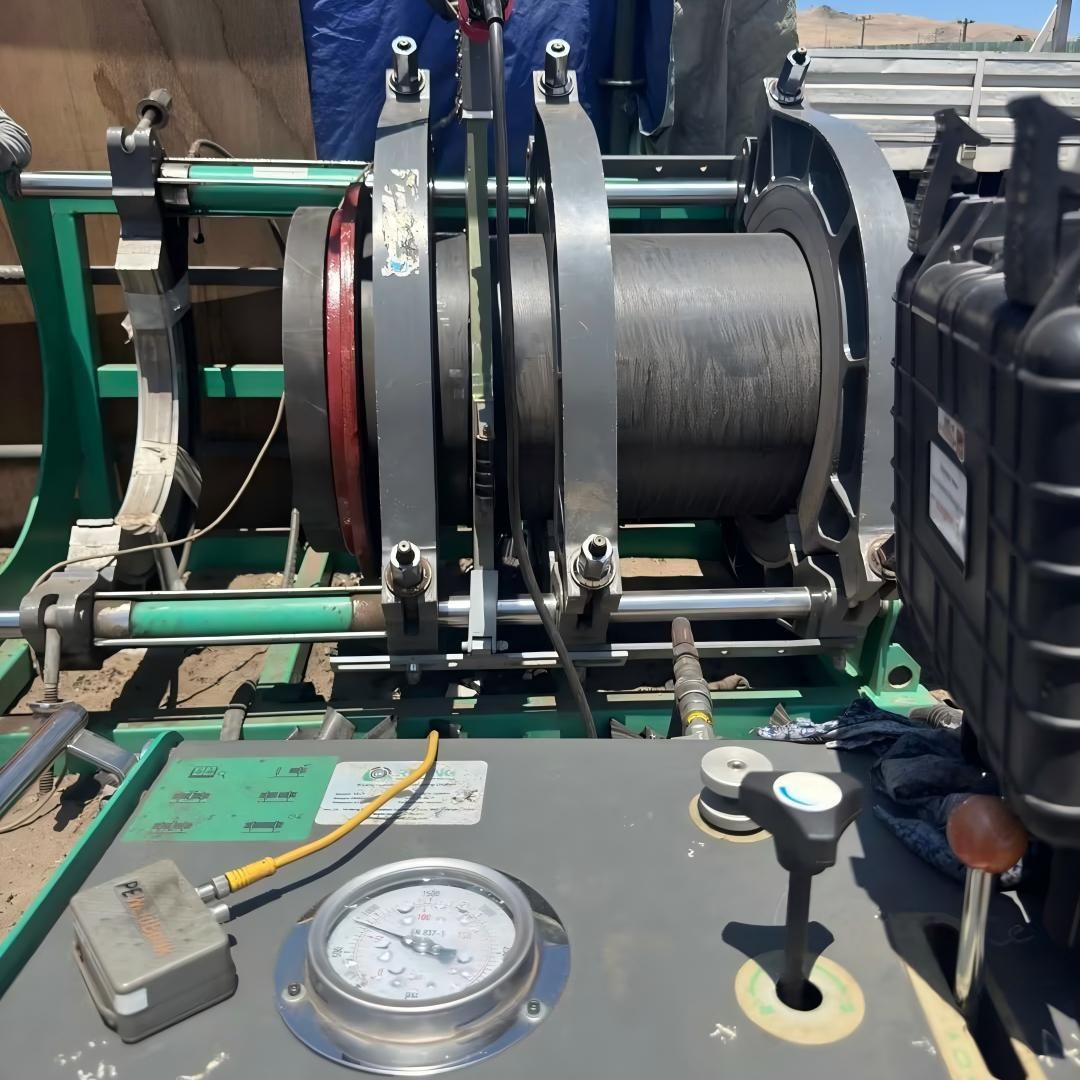

As global infrastructure demands expand and environmental standards tighten, HDPE (High-Density Polyethylene) pipes have become the material of choice for water, gas, and industrial networks. To ensure leak-free joints and long-lasting performance, contractors rely on HDPE butt fusion machines—the most effective solution for joining thermoplastic pipes.

In this article, we explore the top 5 applications of HDPE butt fusion machines in modern infrastructure projects and how choosing the right equipment—like the ones from Riyang Welding—can significantly enhance productivity and reliability.

1. Municipal Water Supply Networks

HDPE pipes are widely used in municipal water distribution systems due to their corrosion resistance, flexibility, and long service life. Butt fusion machines allow for:

.Installation of large-diameter pipelines (e.g., up to 3000mm)

.Seamless joints that prevent water leakage

.Compliance with ISO 21307, DVS 2207, UNI10520, ASTM F2620, WIS 4-32-08 mainstream welding standards

Riyang’s V Series and V-CNC Series offer field-proven solutions with hydraulic or CNC controls, ensuring consistent fusion quality and real-time data logging for utility audits.

2. Natural Gas Distribution Systems

When dealing with flammable materials like natural gas, joint integrity is critical. HDPE butt fusion machines are used to install and maintain gas pipelines under high regulatory scrutiny.

Key advantages include:

.Elimination of mechanical fittings and potential leak paths

.Data traceability to comply with global safety standards

.Use in both urban and remote gas network installations

Riyang’s CNC-controlled machines provide automatic pressure and temperature control, ensuring safe, standardized fusion in gas infrastructure projects.

3. Mining and Slurry Transport

In mining environments, pipelines carry abrasive slurry and chemicals, requiring highly durable, pressure-resistant joints. HDPE butt fusion is the preferred welding method due to:

.Resistance to harsh mining conditions

.Ability to fuse large-diameter pipes

.Portable machines that support on-site welding in rugged terrain

Riyang’s high-pressure fusion machines of ARMOR series with rugged frames and IoT modules enable remote diagnostics and uninterrupted field operations.

4. Sewage and Drainage Systems

HDPE pipes in sewage systems need to withstand pressure, corrosion, and shifting soil. Butt fusion creates leak-free joints that are ideal for underground and trenchless installation methods.

Applications include:

.Gravity drainage systems

.Wastewater collection networks

.Culvert installations under highways or industrial sites

The Riyang V160M and V160 are perfect for small-to-medium diameter systems, offering lightweight, manual or semi-automatic solutions for quick deployment.

5. Agricultural Irrigation & Water Management

Agriculture demands high water efficiency and long-distance pipeline networks. HDPE butt fusion allows farmers and irrigation contractors to:

.Lay long pipe runs with minimal fittings

.Ensure leak-free water delivery over time

.Quickly repair or extend existing networks with mobile fusion units

Riyang’s portable fusion machines are compact, durable, and offer easy operator handling—making them an ideal fit for rural and farm-based operations.

6. Industrial Piping Systems

HDPE butt fusion machines are increasingly used in industrial piping systems for factories, processing plants, and chemical facilities. These environments demand high-performance joints that can handle aggressive media, fluctuating pressures, and space-limited installations.

HDPE fusion in industrial systems offers:

.Chemically resistant and pressure-rated joints for demanding applications

.Safe and leak-free performance under corrosive or high-temperature conditions

.Compact fusion units that suit confined workspaces or modular piping layouts

Riyang’s FuseNano 110 is the ideal choice for industrial contractors and plant maintenance teams. Its lightweight design, quick hydraulic connection, and easy clamp system allow for efficient welding in hard-to-reach areas—such as under platforms, behind tanks, or within mechanical rooms.

Whether used for new installations or urgent repairs, FuseNano 110 delivers professional-grade fusion quality with unmatched portability.

Why Choose Riyang for Infrastructure Fusion Projects?

With over 15 years of expertise and customers across 60+ countries, Riyang Fusion Manufacturing delivers a full spectrum of:

.Manual to CNC Butt Fusion Machines (20mm–3000mm)

.HDPE Fitting Fabrication Equipment (for elbows, tees, crosses and wye)

.IoT-enabled control systems for remote support and data reporting

.Custom-built solutions for infrastructure contractors worldwide

Whether you're building a new gas grid or repairing an old waterline, Riyang has the equipment and expertise to support your goals—efficiently and reliably.

Conclusion

HDPE butt fusion machines play a critical role across diverse infrastructure sectors—from clean water and gas to mining and agriculture. Understanding where and how to deploy the right equipment can help your project meet performance, safety, and budgetary requirements.

Visit our product catalog to explore Riyang’s full range of HDPE fusion machines tailored to infrastructure applications.