What is the Specific Operation Process of the Manual Butt Welding Machine?

- Share

- Issue Time

- Jan 22,2022

Summary

The manual butt fusion machine is suitable for the butt welding of HDPE, PE, PVDF, and other plastic pipes, and it is easy to operate. This article will specifically introduce the characteristics and operating procedures of the manual butt fusion machine.

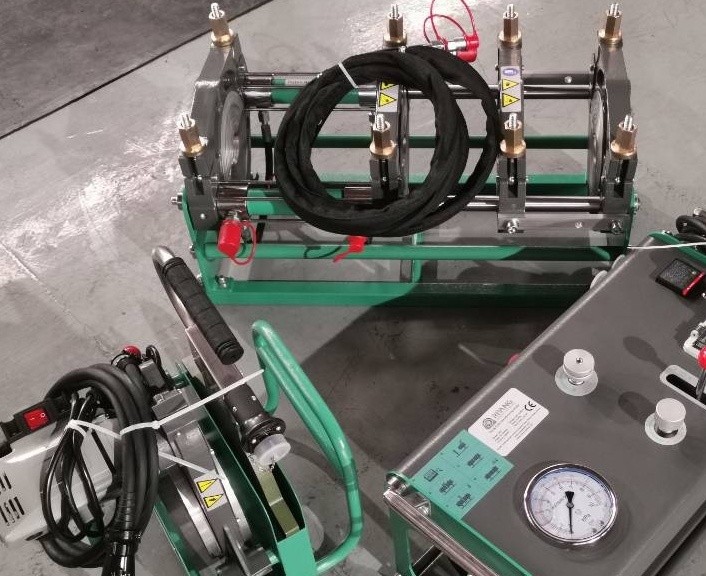

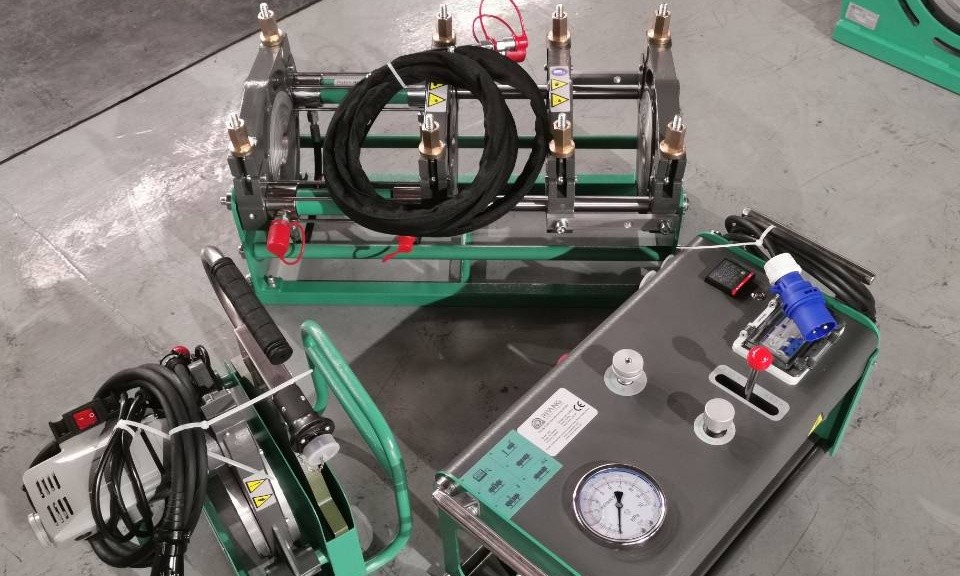

The manual butt fusion machine is composed of a frame, a milling cutter, a heating plate, and a hydraulic control box. The difference from other butt fusion machines is that there is no hydraulic machine. The following are the characteristics and operating procedures of the manual butt fusion machine.

Features

(1) Suitable for hot-melt butt joints of plastic pipes such as HDPE, PE, and PVDF.

(2) The whole machine is composed of a hydraulic station, electrical box, frame, heating device, and milling device.

(3) Split structure, the parts are light and easy to move, the fixture is separated from the operating platform, and the ditch operation is easy.

(4) The docking pressure is provided by the hydraulic power source, and the cutting pressure is provided by the three-phase power source, which makes the whole machine reliable and stable.

(5) The fixture adopts a double ferrule superimposed structure, and the pipes have high docking accuracy and are easy to adjust the amount of misalignment.

(6) The electromagnetic reversing valve is used to control the advance and retreat of the oil cylinder, which makes the operation easier.

(7) The heating system adopts intelligent electronic temperature control, and the temperature control accuracy is more accurate and intuitive.

Operating procedures

(1) Connect the oil pipe, the electric heating plate, and the milling cutter power cord.

(2) Plug in the main power cord, turn on the main power switch and hydraulic motor switch on the left side of the chassis.

(3) Set the heating temperature to 220℃ by setting the switch. Turn on the heating switch.

(4) Fix the pipes to be connected to both ends of the fixture. The gap between the two pipes is suitable to fit the milling cutter head.

(5) Put on the milling cutter head and mill the butt end flat. Start the milling cutter first, and then start the oil cylinder to move forward slowly (the cutting pressure should be adjusted from small to large to move the oil cylinder slowly. The cutting pressure should not be greater than 3Mpa). When continuous cutting occurs, remove the milling cutter head. Straighten the butt joints by adjusting the tightness of the fixture (turn the pipe if necessary) so that the misalignment amount is not more than 10% of the wall thickness.

(6) When the heating plate reaches the set temperature, place the heating between the two ends of the fixture.

(7) Press and hold the hydraulic switch "in", press both ends of the pipe to the electric heating plate for heating. When the two ends are pressed to reach the corresponding flanging, release the switch to keep the heat absorption state.

(8) After the heat absorption time is reached, press the hydraulic switch to "back" and return to the cylinder. After quickly taking out the heating plate, press the "in" position immediately (the faster the switching time, the better), so that compress the two mating surfaces and then release the button immediately when there is about 3mm flanging.

(9) Cooldown to ambient temperature, and remove the fixed fixture.

(10) End of docking.

In the process of operating the manual butt fusion machine, it is necessary to strictly follow the operating procedures to prevent the final docking effect from being affected. If you want to know more about hot melt butt fusion machines after reading the above, you can get professional solutions by contacting us.

As a professional manufacturer of butt fusion machines, we have accumulated rich design and production experience in this field. We have established a complete quality management system and manufactured in strict accordance with production standards, which can provide customers with high-quality and safe products. At the same time, we can provide customers with thoughtful one-stop service and effective solution technology. If you are interested in our fusion butt machine, please contact us immediately!