How to Butt Weld Large Diameter Pe Pipes?

- Share

- Issue Time

- Mar 12,2022

Summary

This article will introduce the specific methods and precautions for butt welding large-diameter PE pipes for your reference.

PE pipeline has the characteristics of easy construction, fast speed, corrosion resistance, no pollution, and long service life. There are two main methods for PE pipe connection: hot-melt connection and electro-fusion connection.

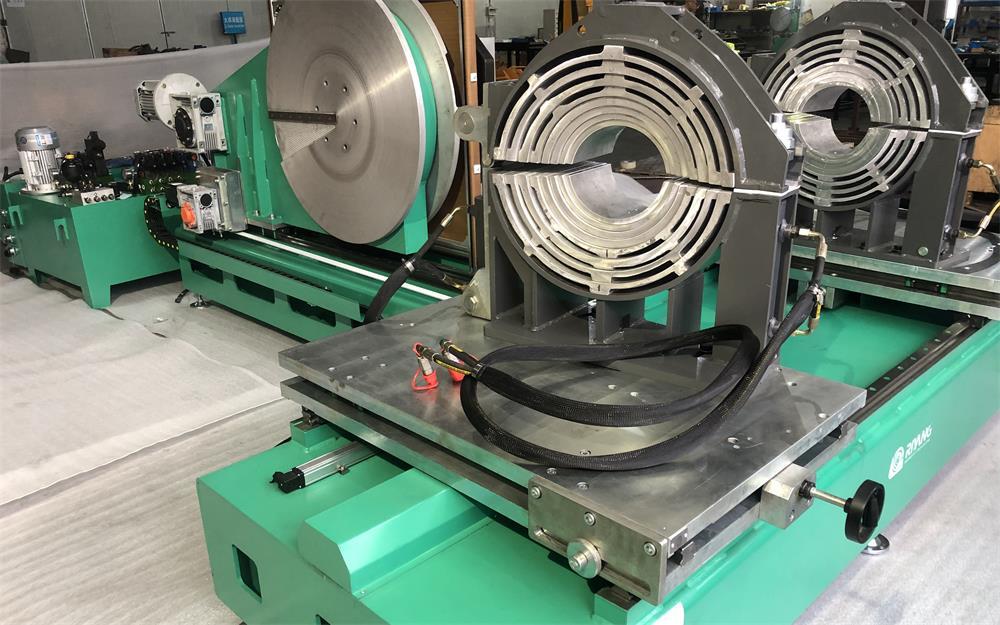

At present, the main pipeline mainly adopts a hot-melt connection. The principle of a hot-melt connection is to close the mating surfaces of two PE pipes to a heating tool to heat them flat until they are melted. After removing the heating tool, the two molten end surfaces close together and keep them under pressure. The joint is cooled to make it a whole. The followings are the steps to use a butt fusion machine to connect large-diameter PE pipes.

1. Material preparation

(1) Turn on the power of each part of the welding machine. 220V, 50Hz alternating current must be used, the voltage change is within ±10%, the power supply should have a grounding wire; at the same time, the surface of the heating plate should be clean and free from scratches.

(2) Connect the pump station and the frame with hydraulic wires. Before connecting, check and clean up the dirt at the joint to prevent dirt from entering the hydraulic system and damaging the hydraulic components; after the hydraulic wire is connected, the joint part should be locked to prevent the danger of the joint being opened during high-pressure work. Input welding data according to the selected working mode: diameter; wall thickness or SDR value; temperature setting of the heating plate; welder code.

2. Clamping

Place the PE pipe or pipe fittings in a flat position, and place them on the butting machine, leaving enough cutting allowance of 10-20mm; according to the PE pipes and fittings to be welded, select the appropriate slip fixtures, clamp the pipes, and prepare for cutting.

3. Cutting

Cut impurities and oxide layers on the welded pipe sections and end faces of pipe fittings to ensure that the two butt joint ends are smooth, clean, and free of impurities.

(1) Open the frame, insert the milling cutter, turn the locking knob, and fix the milling cutter on the frame. When starting the pump station, it should be carried out when the direction control handle is in the neutral position, and it is strictly forbidden to start under high pressure.

(2) Start the milling cutter, close the fixture, and cut the end face of the pipe fitting.

(3) When a continuous cutting is formed, reduce the pressure, open the fixture, and close the milling cutter. This process must be carried out in the order of first reducing the pressure, opening the fixture, and finally closing the milling cutter.

(4) Remove the milling cutter, close the fixture, and check the gap between the two ends of the PE pipe (the gap should not be greater than 0.3mm). When removing the milling cutter from the frame, avoid the collision of the milling cutter with the end face, and re-milling if it has occurred; do not touch the milled end face by hand or be contaminated by oil.

4. Centering

Check the concentricity of the PE pipe (the maximum amount of misalignment is 10% of the pipe wall thickness). When the gap between the two ends and the amount of misalignment cannot meet the requirements, the weldment to be welded should be re-clamped, milled, and the next step can be performed only after it is qualified.

5. Heating

(1) Check whether the temperature of the heating plate is suitable for 210℃~230℃, and the melting length of both ends is preferably 1~2mm.

(2) The red indicator light of the heating plate should be on or flashing. After the red indicator light on the heating, the plate lights up for the first time, wait for 10 minutes to use it to make the temperature of the entire heating plate uniform.

(3) Test and record the drag pressure P0 of the system. The dragging pressure of each welding port needs to be measured; when the dragging pressure is too large, it can be solved by using short pads.

(4) Place a heating plate with a suitable temperature on the rack, close the fixture, and set the system pressure P1. P1=P0+ seam pressure.

(5) When the bulge between the PE pipes is uniform and the height reaches the requirement, reduce the pressure to approximately the drag pressure, and press the endothermic timer button at the same time to start recording the endothermic time. P2=P0+endothermic pressure (endothermic pressure is almost zero).

6. Switching

(1) Remove the heating plate, quickly let the two hot melt end faces adhere, and pressurize. In order to ensure the quality of the melt butt joint, the shorter the switching period, the better.

(2) After the heat absorption time is reached, quickly turn on the machine and remove the heating plate. When taking the heating plate, avoid collision with the molten end surface; if it has occurred, the entire welding process should be restarted after the molten end surface has been completely cooled.

7. Fusion butt

This is the key to welding. The butt joint process should always be carried out under melting pressure, and the curling width should be 1~2mm.

8. Cooling

Keep the docking pressure constant, and let the interface cool down slowly. The length of the cooling time is based on the roughness of the curling by hand, and no heat is felt.

Close the fixture quickly, and within the specified time, quickly adjust the pressure to P3, and press the timer at the same time to record the cooling time. P3=P0+cooling pressure After the fixture is closed, the pressure should be increased evenly, not too fast or too slow, and should be completed within the specified time; in order to avoid the formation of false welding, virtual welding, this pressure should be maintained until the weld is completely cooled.

9. Complete docking

After the cooling time is reached, the pressure is reduced to zero, the clamp is opened, the welded pipe (pipe fitting) is removed, the docking machine is removed, and the next interface connection is prepared again. Before unloading the pipe, the system pressure must be reduced to zero; if the welding machine needs to be moved, the hydraulic wire should be removed, and dust-proof work at the joint should be done in time.

If you want to know more about the butt welding machines after reading the above, please refer to our previous news.

RIYANG is a butt welding machine manufacturer with many years of experience. We put our customers' needs first in everything we do, aiming to provide customers with effective solutions. For this, we are equipped with a professional manufacturing team and strict quality inspection system, which can control the quality of products in all aspects. At the same time, we will continue to adjust and upgrade R&D technology and design solutions according to the diverse needs of Russian users. If you want to buy our hot melt butt machine, please contact us immediately!