How Does a Plastic Welding Machine Work?

- Share

- Issue Time

- Apr 22,2022

Summary

Common plastic welding machines include ultrasonic plastic welding machines, hot plate welding machines, laser plastic welding machines, etc. Let's take a look at the working principle of plastic welding machines!

Common plastic welding machines include ultrasonic plastic welding machines, rotary friction plastic welding machines, hot plate welding machines, laser plastic welding machines, and orbital vibration friction welding machines. Let's take a look at the working principle of plastic welding machines!

1. The working principle of the ultrasonic plastic welding machine

The principle of ultrasonic welding is to convert 50/60Hz current into 15, 20, 30, or 40kHz electrical energy through an ultrasonic generator. The converted high-frequency electrical energy is converted into mechanical motion of the same frequency again by the transducer, and then the mechanical motion is transmitted to the welding head through a set of amplitude modulator devices that can change the amplitude.

The welding head transfers the received vibration energy to the joint of the workpiece to be welded, where the vibration energy is converted into heat energy by friction, melting the plastic.

Ultrasound can be used not only to weld hard thermoplastics but also to process fabrics and films. The main components of an ultrasonic welding system include an ultrasonic generator, transducer/modulator/horn triplet, die, and frame.

2. The working principle of rotary friction plastic welding machine

Rotary friction plastic welding machines are generally used to weld two round thermoplastic workpieces. During welding, one workpiece is fixed on the bottom mold, and the other workpiece rotates on the surface of the fixed workpiece.

Due to a certain pressure acting on the two workpieces, the heat generated by the friction between the workpieces can melt the contact surfaces of the two workpieces and form a forbidden and airtight bond. The positioning spin fusion is to rotate at a set time and stop at the set position instantly, becoming a permanent fusion.

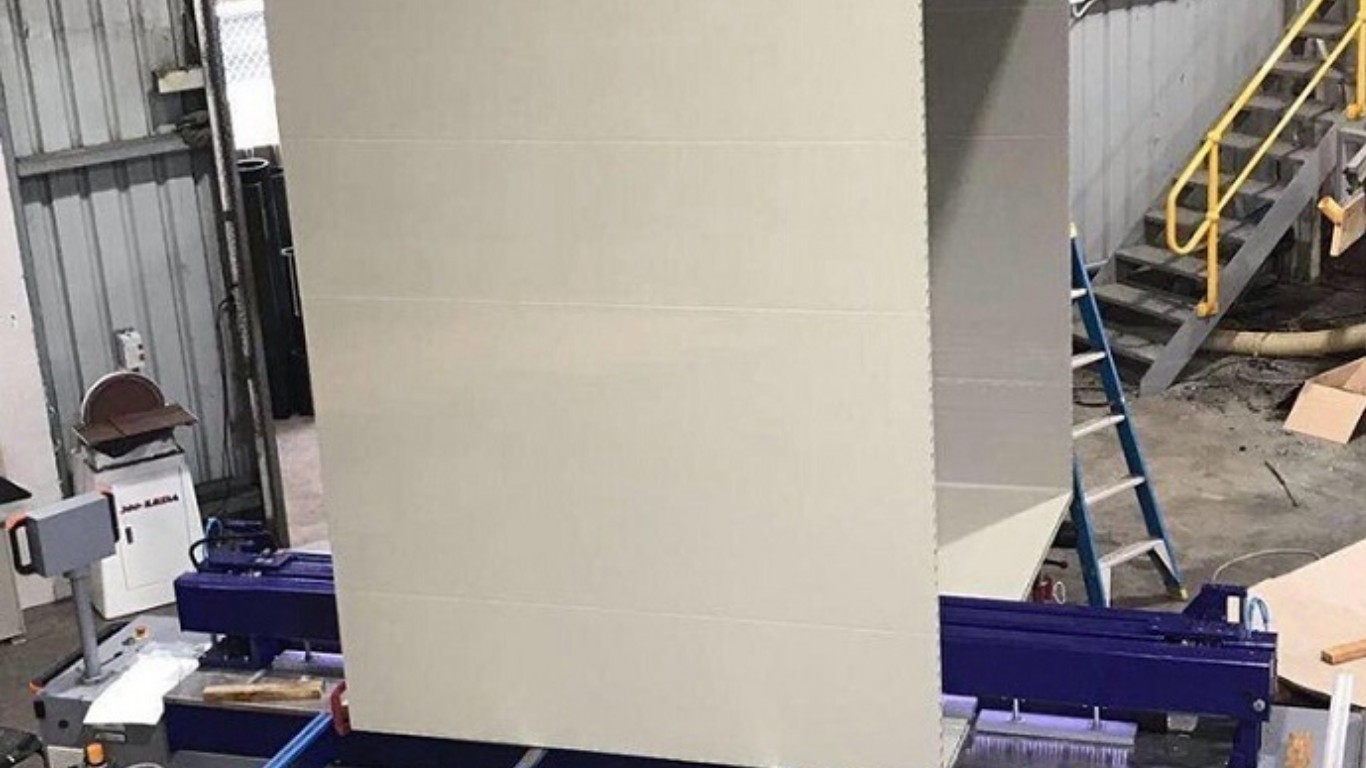

3. The working principle of the hot plate welding machine

Hot plate welding machines mainly weld plastic parts through a temperature-controlled heating plate. When welding, the heating plate is placed between two plastic parts, and when the workpiece is pressed against the heating plate, the plastic begins to melt.

After a pre-set heating time has passed, the plastic on the surface of the workpiece will reach a certain degree of melting. At this time, the workpiece will be separated to both sides, the heating plate will be removed, and then the two workpieces will be merged together. When a certain welding time and After the welding depth, the entire welding process is completed.

4. The working principle of laser plastic welding machine

The working principle of the laser welding machine is to make the light/laser ray pass through one plastic part and irradiate the surface of the other plastic part (that is, the welding surface); the welding surface is heated and melted after fully absorbing the beam energy; The pieces apply an adjustable clamping force to hold them tightly together.

Compared with other existing plastic welding processes, the advantage of the laser welding process is that the light/laser rays can heat and weld the entire welding surface at the same time, and the welding effect is more significant.

5. The working principle of linear vibration friction welding machine

Linear vibration friction welding uses the frictional heat energy generated at the contact surface of two workpieces to be welded to melt the plastic. The thermal energy comes from the reciprocating movement of a workpiece on the other surface with a certain displacement or amplitude under a certain pressure.

Once the desired degree of welding is achieved, the vibration will stop, while a certain amount of pressure will still be exerted on the two workpieces, allowing the just welded part to cool and solidify to form a tight bond.

6. The working principle of orbital vibration friction welding machine

Orbital vibration friction welding is a method of welding that utilizes frictional heat energy. During orbital vibration friction welding, the upper workpiece orbits at a fixed speed—circular motion in all directions. Movement can generate thermal energy that brings the welded part of the two plastic parts to the melting point.

Once the plastic begins to melt, the movement stops, and the welded parts of the two workpieces solidify and are firmly joined together. The small clamping force results in minimal deformation of the workpiece and workpieces up to 10 inches in diameter can be welded with applied orbital vibration friction.

The "working principle of plastic welding machine" is introduced here. If you plan to buy a plastic welding machine, please contact us!

RIYANG is a professional custom plastic welding machine manufacturer in China. We offer a wide range of products to meet the needs of field and workshop projects. Our products operate all over the world due to reliability, creativity, and cost-effectiveness. At RIYANG, we are committed to making reliable machines for every application and making sure your choice is the right one.