Automatic Butt Fusion Machine V250CNC20 90MM-250MM (2" IPS - 8" IPS)

- Model

- V250CNC20

Item specifics

- Certificate

- CE, ISO9001

- Packing Material

- Plywood Box

- MOQ

- 1 set

- Working Range in mm

- (63*) 90mm-250mm

- Working Range in inch

- (2*) 3" - 8"IPS

- Working Pressure Range

- 0 - 80Bar

- HDPE Welding Standard Applied

- ISO21307, DVS2207 etc

- Operation Type

- Automatic

Review

Description

Automatic Butt Fusion Machine V250CNC20 90MM-250MM (2" IPS - 8" IPS)

The RIYANG CNC2.0 is a premium, high-stability automatic butt fusion machine powered by a Siemens PLC. It is manufactured to meet rigorous standards including ISO 12176-1 for butt-fusion welding of thermoplastic pipes and the EU Machinery Directive 2006/42/EC.

The system supports pre-programmed welding standards conforming to major industry standards such as DVS, ISO, and ASTM. Custom standards can be incorporated on demand.

Welding records can be exported via USB, saved as PDF, and key parameters (time, operator, standard, welding result) can be printed on adhesive labels for on-site traceability. The machine’s memory supports storing up to 10,000 weld logs.

During welding, the system provides real-time alerts if key parameters—voltage, temperature, or pressure—are outside specified ranges, enabling immediate corrective action and maximizing weld integrity.

Welding parameters can be tailored to specific pipe materials and ambient conditions, enhancing flexibility and ensuring optimal weld results under varied conditions.

Backed by a 2-year industry-leading warranty.

|

Product Details

|

|||

|

Welding Range O.D. (mm)

|

(63, 75)* 90mm - 250mm

|

Welding Range O.D. (inch)

|

2" IPS - 8" IPS

|

Power Supply | 220V±10%, 50/60HZ | Temperature Range | MAX. 280℃ |

Heater Power | 2.0KW | Packing Dimension | 830*520*500 MM |

|

Trimmer Power

|

0.85 KW

|

560*540*600 MM

|

|

|

Pump Power

|

1.1 KW

|

650*340*380 MM

|

|

Working Pressure Range | 0 - 80 BAR | Gross Weight | 192 KG |

Integrated User Interface

Features a unified control panel that enhances operator efficiency and minimizes errors. Mechanical push-buttons are accompanied by status indicator lights, allowing real-time monitoring of the machine's operating status.

Versatile Control Box

One control box is compatible with machine models 160, 200, 250, 315, and 355, enabling significant cost savings for users. It also allows for easy upgrades from manual to automatic configurations.

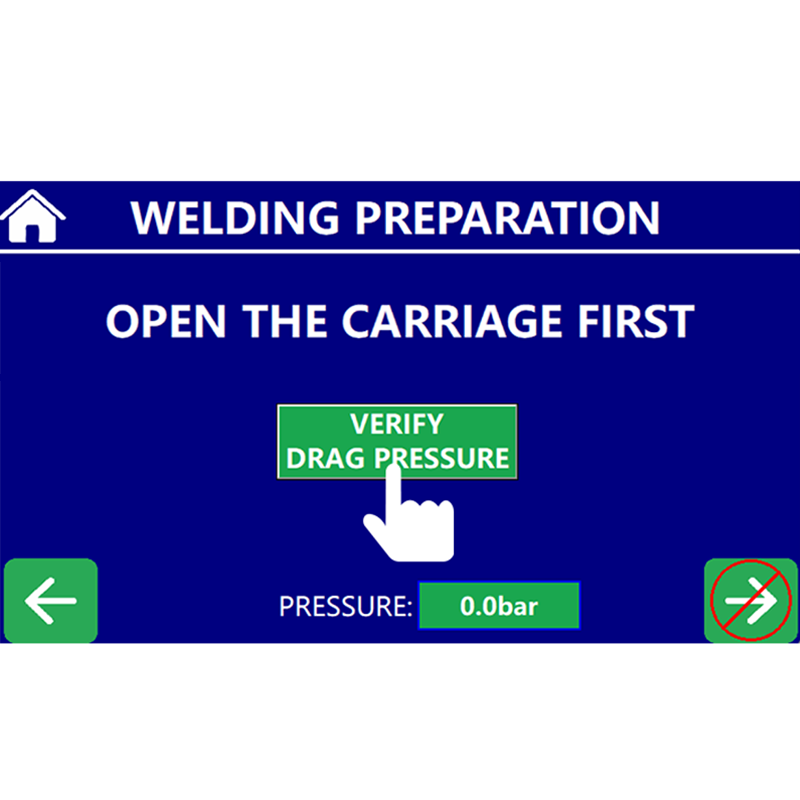

Effortless Drag Pressure with Just One Click

Achieve precise drag pressure effortlessly with a single click, streamlining the welding process and improving operational efficiency.

Remote Diagnostics & Firmware Upgrades

The system supports remote troubleshooting and OTA software updates, allowing technical teams to identify and resolve issues without the need for on-site service.