Pipe Band Saw TPS450 90mm-450mm (3" IPS - 18" IPS)

- Model

- TPS400

Item specifics

- Certificate

- CE, ISO9001

- Packing Material

- Plywood Pallet

- MOQ

- 1set

- Working Range in mm

- 90mm - 450mm

- Working Range in Inch

- 3" IPS - 18" IPS

- Cutting Angle Range

- -45° - 67.5°

Review

Description

Overview

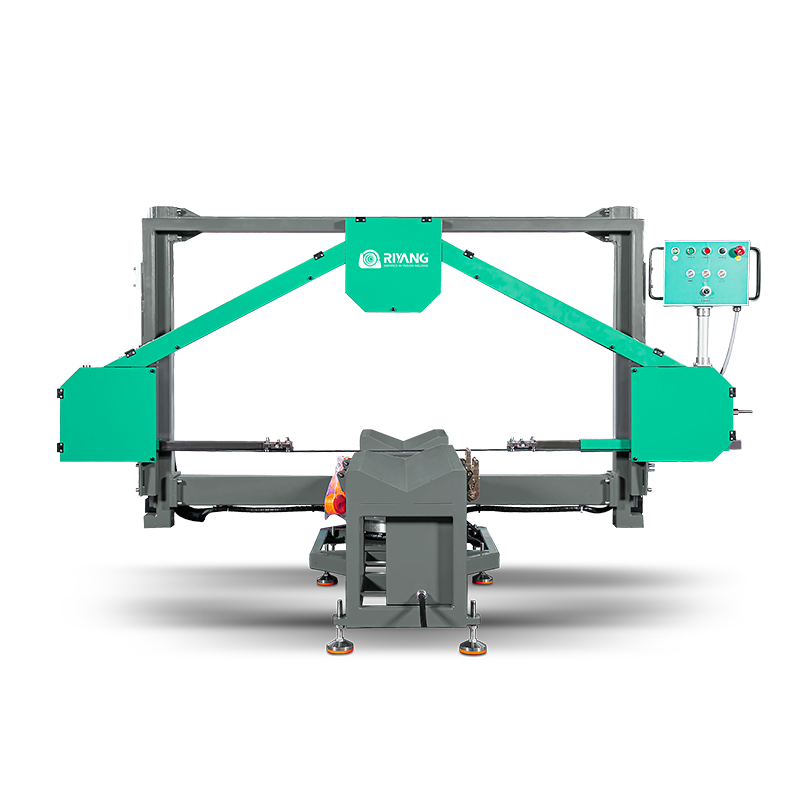

TPS450 is an electric workshop band saw for thermoplastic material(HDPE, PP, PVDF, PPR, PVC) pipes from 90mm to 450mm diameter. Thanks to the slewing bearings, the machine body can be easily moved by manual. And the cutting angle is adjustable with precision from -45°to 67.5°. It could works ideally with ATLA fittings fabrication machine for various kinds of fittings.

The equipment is provided with remote control panel, which give the chance to the operator work in a safety distance from the cutting area. By the control panel, the operator can control the automatic movement of the saw (up/down) and also regulate the cutting speed.

|

Product Parameter

|

|||

|

Cutting Range

|

OD 90 mm - 450 mm

|

Max. Cutting Angle

|

67.5º

|

Power Supply | 380 V, 3 P, 50/60 hz | Materials | HDPE, PP, PVDF, PPR, PVC |

Rated Power | 2.5 kW | Cutting Angle Error | ≤ 1° |

Line Speed | 0 - 255 m/min | Feeding Speed | Adjustable |

|

Footprint

|

180 cm * 200 cm

|

Net Weight |

780 kgs

|

Standard Composition

- Pipe supporting stand

- Control panel

- Saw body

- Clamping belt

On Request

+Automatic angle adjustment

+Pipe holding mechanic

Highlight Features

No Oil

A machine driven solely by electric cylinders, without hydraulic cylinders, eliminates the worries of oil leaking and need for hydraulic oil replacement, resulting in cleaner operation, lower maintenance, and improved energy efficiency.

Electric Cylinder

The electric cylinder facilitates high-speed, smooth movement of the saw carriage, significantly boosting travel speed and synchronizing accuracy while reducing operating noise, thereby enhancing overall equipment efficiency and creating a more comfortable work environment.

- 45° - 67.5°

This HDPE pipe cutting saw is engineered for efficiency and precision. It allows angle cutting from -45° to 67.5° simply by rotating the saw blade housing—no need to reposition the pipe. This greatly enhances cutting efficiency, especially when fabricating fittings such as WYE joints, making the operation faster, easier, and more labor-saving.