Hydraulic Butt Fusion Machine V1600 1000MM-1600MM (42" IPS - 63" IPS)

- Model

- V1600

Item specifics

- Certificate

- CE, ISO9001

- Packing Material

- Plywood Box

- MOQ

- 1set

- Working Range in mm

- 1200mm - 1600mm

- Working Range in Inch

- 42'' IPS - 63'' IPS

- Working Pressure Range

- 0 - 160Bar

- Welding Standard Applied

- ASTM F2620, ISO21307 SHP

Review

Description

Hydraulic Butt Fusion Machine V1600 1000MM-1600MM (42''IPS - 63''IPS)

RIYANG V1600 Butt Fusion Welding Machine is engineered to excel in a diverse range of application fields, ensuring robust and precise fusion welding. This includes but is not limited to:

● Water Infrastructure: Perfect for joining thermoplastic pipes in water supply networks, guaranteeing secure and leak-free connections.

● Gas Distribution Systems: Ideal for welding pipes in gas distribution systems, providing a reliable solution for maintaining gas infrastructure integrity.

● Industrial Pipelines: Suited for various industrial applications utilizing thermoplastic pipes, ensuring durable fusion joints.

● Mining Industry: Delivering efficient fusion welding for pipelines critical to mining operations. Whether for transporting water, chemicals, or other resources, it ensures dependable and durable connections.

|

Product Details

|

|||

|

WELDING RANGE O.D.

|

1000MM - 1600MM

|

WELDING RANGE INCH

|

42" - 63" IPS

|

POWER SUPPLY | 380V±10%, 50/60HZ | TEMPERATURE RANGE | MAX. 320℃ |

HEATER POWER | 42.0 KW | PACKING DIMENSION | 3540*2600*2300 MM |

|

TRIMMER POWER

|

7.5 KW

|

2340*1700*2000 MM

|

|

|

PUMP POWER

|

3.0 KW

|

/

|

|

WORKING PRESSURE RANGE | 0 - 160 BAR | GROSS WEIGHT | 7800 KG |

Frame Design: Adopting the innovative "3+1" design, the frame provides substantial assistance when welding short spigot fittings. The robust construction ensures stability during operation. Key hydraulic components, including oil seals, quick connectors, and pressure valves, are imported from top-notch suppliers in Japan, the United States, and Italy.

Heating Plate: The increased thickness of the heating plate guarantees minimal temperature differentials, contributing to uniform and reliable fusion. The use of industry-leading Teflon material reduces the adhesion of the heating plate to melted plastic, ensuring smooth operation.

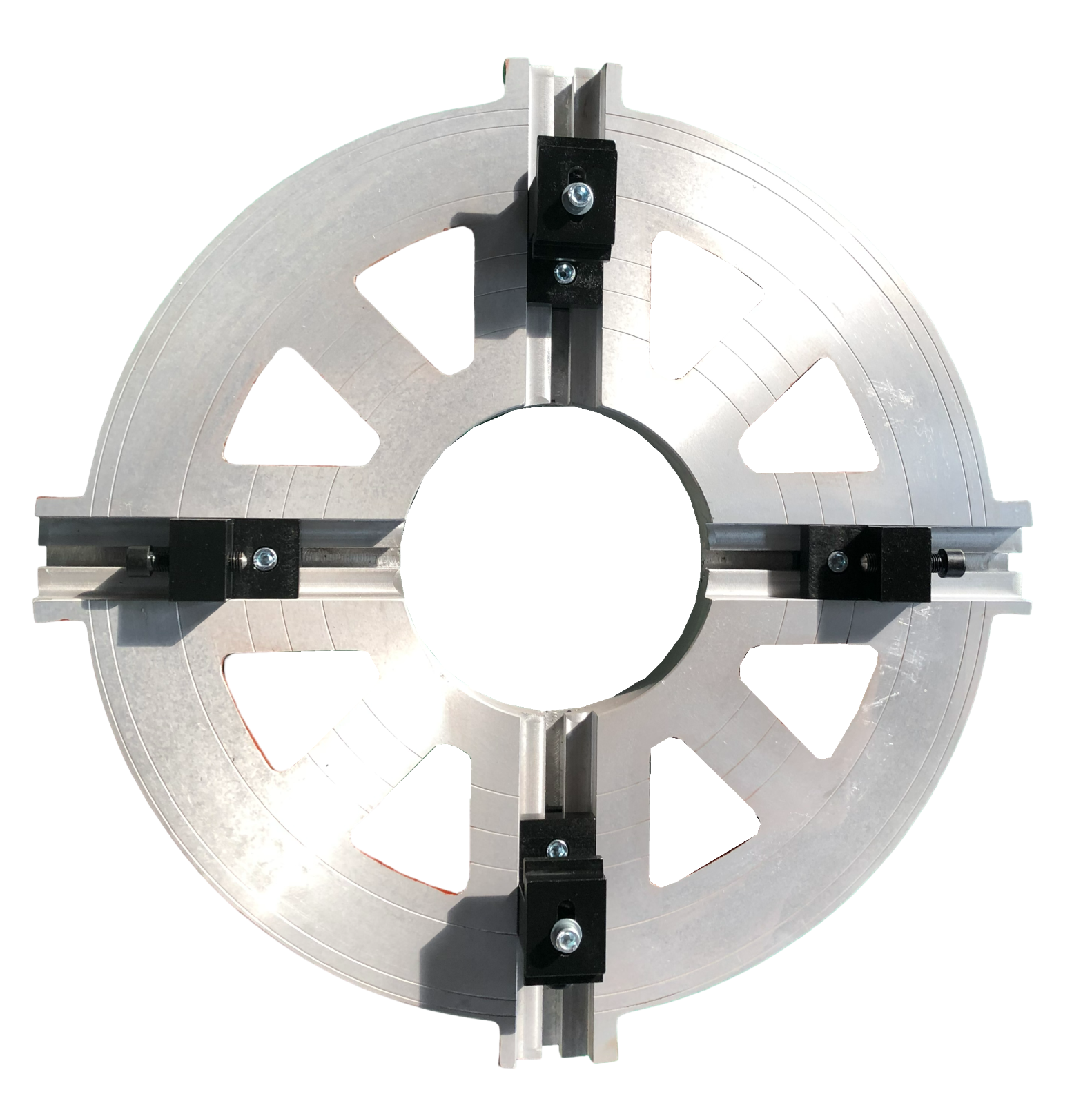

Milling Cutter: Equipped with a powerful milling cutter, featuring a single-sided double-blade design for enhanced efficiency in pipe milling. The design facilitates more effective and precise milling of pipes.